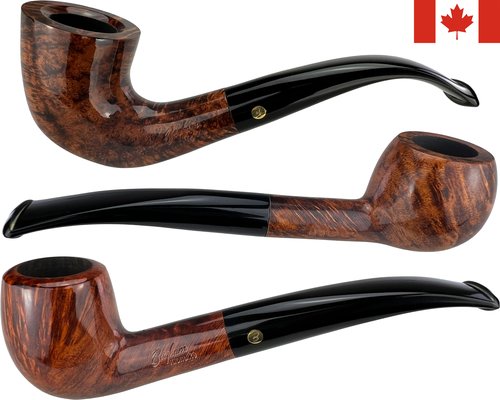

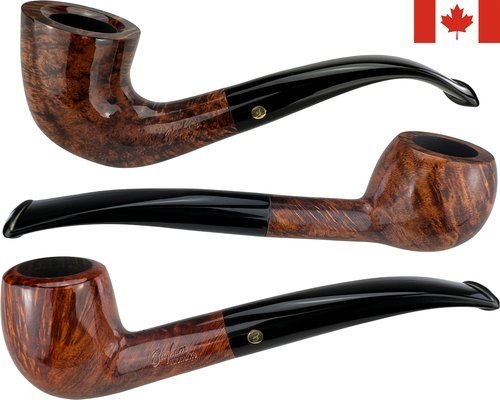

Brigham Pipes: Tradition and Innovation Since 1906

In 1906, Roy Brigham opened a pipe repair workshop in Toronto after completing his training with an Austrian pipe maker. By 1918, the business had grown to five employees, reflecting the brand's economic success. Through experience with numerous pipes and designs, Roy Brigham identified the weaknesses in many models. At the same time, he was driven by the common complaint of pipe smokers about tongue bite—a problem that would shape his future endeavors.

Roy Brigham and the Innovation of Pipe Filters

Brigham soon began crafting his own pipes, which stood out for their superior quality and design. In 1938, Roy's son Herb joined the company, and together they conducted intensive research to combat tongue bite. Their studies revealed that specific pipe filters could significantly reduce this effect.

They then developed filters using local and imported materials. However, filters made from bamboo and sugar maple ("Rock Maple") proved particularly effective. Since bamboo was scarce and expensive, they decided to exclusively use local maple wood.

Small Masterpieces of Maple Wood: Brigham Rock Maple Filters

The Brigham Rock Maple Distillators Filters consist of a maple wood tube with an aluminum tip. Measuring approximately 9 cm, the filter is partially placed in the shank and partially in the stem. Its strengths lie in filtering smoke and absorbing moisture. Unlike European filter systems, these filters are reusable. After rinsing and drying, they can be used again, with filtration effectiveness diminishing after 20 to 30 uses.

Eco-Friendly Alternative

Since the filters are primarily made of locally sourced maple wood and are reusable, they offer a sustainable alternative to conventional disposable filters. This filter system avoids waste and does not rely on fossil or hard-to-decompose materials like activated carbon or meerschaum. Additionally, maple wood is abundant in the Toronto region.

Brigham Pipes: Canadian Craftsmanship with History

In the 1960s, Brigham pipes reached their peak, with over 40 employees working in production. However, a growing shortage of skilled labor led to a significant portion of production being relocated to the European Union in 2001, where it continues to this day.